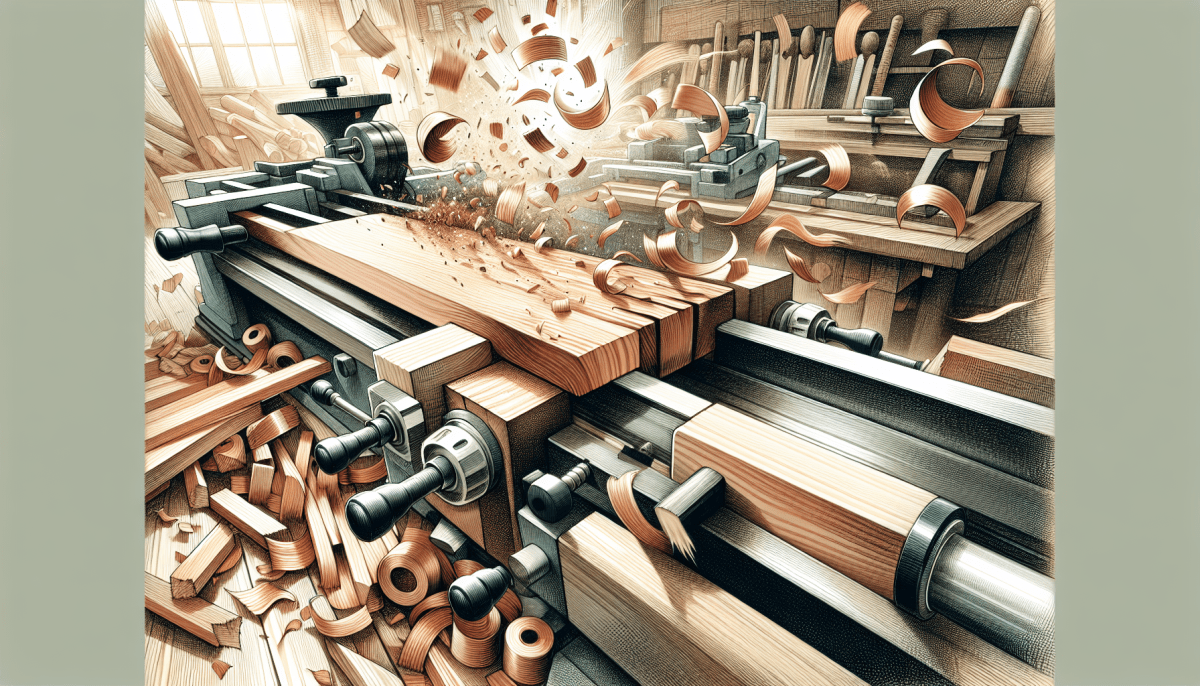

Getting into woodworking is exciting, and knowing the basics can make all the difference. If you're just starting out, a jointer is a tool that you'll want to get familiar with. It helps you create flat surfaces on your lumber, making it way easier to assemble your projects accurately.

First things first, understand how to operate the jointer safely. Always wear safety goggles to protect your eyes from flying wood chips. Make sure your hair is tied back and your clothing is snug, so you don’t risk getting caught in the machine. A little safety precaution goes a long way!

Next, learn the settings for your jointer. Adjust the cutter height properly based on the thickness of the wood you're working with. Start with small adjustments to avoid taking off too much material at once. You want to get that perfect flat surface without ruining your wood.

Once you're set up, practice feeding the wood through smoothly. Keep a steady pace and don’t rush it. If you feel any resistance, stop and check your settings. This will help you avoid mistakes and make sure you get the cleanest cuts.

Finally, don't hesitate to take notes as you learn. Keep track of what settings work best for different types of wood. This will save you time and help you get better results as you continue your woodworking journey. Happy woodworking!

Choosing the Right Jointer for Your Projects

Choosing the right jointer for your woodworking projects can make all the difference. You want something that fits your skill level, the space you have, and the types of projects you plan to tackle. A good jointer flattens and squares edges, making your boards ready for assembly. Here’s what to think about before you buy.

First, consider the size of the jointer. If you're working in a small garage or workshop, a compact model could be ideal. Smaller jointers are portable and easy to store. On the other hand, if you have the space and often work with larger boards, going for a wider jointer will save you time and make projects smoother.

Next, think about the cutter head. A straight knife cutter head is common and gets the job done, but a helical cutter head is a game-changer. It provides a smoother finish and reduces tear-out on harder woods. If you're planning to work with various wood types, investing in a helical cutter head might be worth it.

Don't forget about the features that enhance usability. A jointer with built-in dust collection keeps your workspace cleaner, letting you focus on your projects. Adjustable fences and smooth operation make a huge difference when you’re trying to get precise angles and edges.

Finally, read reviews and consider your budget. There are great options for every price range, but you want to make sure you’re buying something reliable. Find a jointer that balances quality and cost, and you’ll be set for your woodworking adventures!

Tips for Using Your Jointer Effectively

Using a jointer can really take your woodworking projects to the next level, but a few tips can help you get the best results. First off, always make sure your jointer is properly adjusted. Check the blades for sharpness and alignment. Dull blades can lead to tear-out and an uneven finish, so keep them in top shape.

When you start, feed your wood into the jointer at a steady speed. Going too fast or slow can lead to inconsistencies. You want the jointer to do its magic without any hiccups. If you’re jointing a wide board, use a push block to help guide it evenly. This can prevent snags and give you a smoother finish.

Don’t forget to check your wood for warping or cupping. A little prep work saves a ton of hassle later. Joint one face and then one edge for the best results. That way, you have a flat reference surface to work with, making future cuts much easier.

Lastly, keep your workspace clean. Shavings and dust can impact the jointer's performance. A tidy area helps you focus and keeps everything running smoothly. Remember, the more you practice, the better you’ll get, so don’t hesitate to experiment and find what works best for you!

Maintaining Your Jointer for Longevity

Keeping your jointer in top shape is all about regular maintenance. A well-cared-for jointer will not only last longer but also deliver better performance. Here’s what you need to do.

First off, always keep the knives sharp. Dull blades can lead to tear-out and cause more wear on your machine. Check them regularly and replace or sharpen them when needed. You’ll notice a big difference in the quality of your cuts.

Next, clean the table and entire machine regularly. Dust and shavings can build up and affect the precision of your cuts. Use a brush or vacuum to keep things tidy. It’s a simple task, but it makes a huge difference.

Lastly, don’t forget about lubrication. Make sure to oil any moving parts per the manufacturer's recommendations. This keeps everything running smoothly and helps prevent rust. A little oil can go a long way in keeping your jointer happy!